Enhancing Membrane Filtration Efficiency with Grundfos Smart Filtration Suite (SFS)

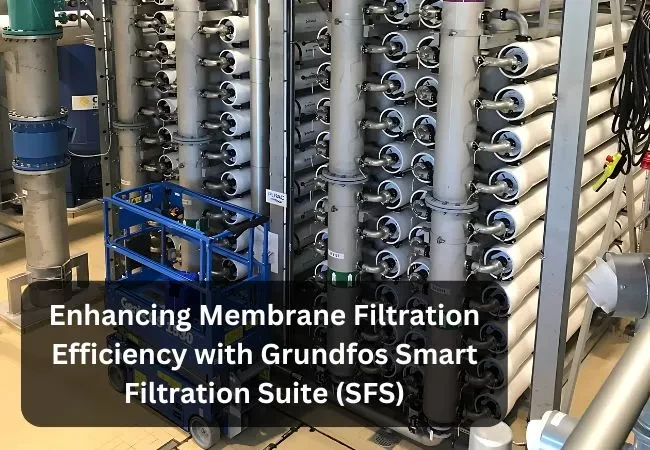

In the quest for improving water treatment processes, Grundfos has been at the forefront of developing advanced control systems. In 2019, an extended field test was conducted for a Grundfos control system designed to optimize membrane filtration. This testing took place at a prominent water treatment plant (WTP) that supplies around 5 million cubic meters of drinking water annually. The facility processes surface water through a series of steps, including rapid sand filtration, Ultrafiltration (UF), coagulation, pH adjustment, and UV disinfection.

The WTP underwent a significant upgrade in 2016 to enhance its UF capacity, achieving a maximum permeate flow rate of 1080 cubic meters per hour. This upgrade was essential for meeting stringent microbiological standards and improving the removal of natural organic matter (NOM). The plant’s two-stage UF system, equipped with in-line coagulation and a secondary UF stage, was designed to address site-specific challenges such as limited sewer capacity and coagulant residues, achieving a recovery rate of over 90%.

The Solution: Implementing the Smart Filtration Suite for Enhanced Efficiency

Grundfos introduced its Smart Filtration Suite (SFS) into the UF system to enhance operational efficiency. The SFS was implemented to fine-tune critical parameters such as backwash frequency, duration, and chemical cleaning timing. Initially deployed in a "GhostMode," the SFS monitored and logged its suggestions without making immediate operational changes. This approach allowed for a comprehensive evaluation of the system's recommendations.

The SFS identified opportunities to optimize the filtration cycle length and reduce the frequency of chemically enhanced backwash (CEB). Specifically, it suggested doubling the interval between CEB events. To validate these recommendations, the plant operators extended the CEB interval by 20% on two out of four racks.

Results Achieved: Significant Savings and Enhanced Efficiency

The implementation of the SFS led to notable improvements. By extending the CEB interval, the plant achieved annual savings across the system, with no adverse effects on the filtration process. This case highlights how even minor adjustments in operational parameters, guided by advanced control systems like the SFS, can lead to significant cost savings and enhanced efficiency.

Grundfos’s Smart Filtration Suite exemplifies how advanced control technologies can optimize water treatment processes, demonstrating substantial benefits without compromising operational performance.

Why Choose Alantech for Grundfos Smart Filtration Solution?

Being a renowned grundfos pump suppliers with years of experience in the industry, our team of experts has in-depth knowledge of Grundfos products. Our extensive knowledge of the products helps you choose the best grundfos pumps and ensures that you receive the best guidance and support. From pumps to filtration systems, we offer a wide range of Grundfos products. Our team also focuses on providing exceptional customer service and stays updated on the latest Grundfos products and technologies.

With our expertise and extensive knowledge, Alantech is the trusted water treatment plant manufacturers that helps you find the perfect Grundfos solution for your specific needs.