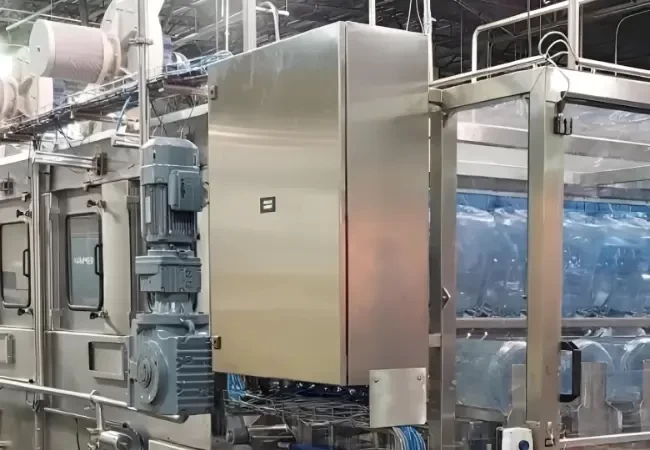

5-Gallon Bottle Washing Machine

Factors influencing cleaning performance

TIME

The treatment time is the result of a washing cycle which can be customized in terms of number of stations and phases according to the customer standard and requirements. Our recommended washing cycle provides 6 main phases: 1. PREWASH - 2. DETERGENT - 3. FIRST RINSE - 4. SANITIZING - 5. SECOND RINSE - 6. FINAL RINSE

TEMPERATURE

The constant monitoring of the temperature is paramount in order to wash the bottles according to the preset values (between 60 and 65°C). An alarm stops the washer in case these set points are not respected.

PRESSURE

To optimize the washing process, the washer is equipped with high pressure system, which:

- Allows to increase the pressure of the washing jet up to 6 bar

- Can be installed on one or more station of the washing phase

- It's particularly indicated for difficult-to-clean bottles (hollow handles, shaped bottles)

CHEMICAL %

MECHANICAL ACTION

Neck Handling

This patented system to grip the neck of the bottle, guarantees important advantages as:

- The possibility to use an high pressure washing jet

- The washing of the external part of the bottle inside the washer, thanks to the possibility of the bottle rotation under the action of brushes

- The washing of the bottle neck

Washing Rotating Nozzles

The washer is fitted with double washing rotating nozzles which guarantee the following advantages:

- The jet of water hits not only the bottom, but the handle and the walls too.

- The nozzles are self-cleaning (the water flow is inverted at the passing of each bottle) and the washing efficiency is therefore guaranteed. The disassembly for maintenance is considerably reduced.

- The beam carrying the bottles is synchronized with the nozzle even in case of chain extension.

Rotary Brushing

- Brushes are motorised and clean the bottle externally. Since they make the bottle spin, the water jet hits not only the bottom but also the sides of the bottle.