Blow Moulding Machine

Welcome to Alantech’s Blow Moulding Machine, where cutting-edge technology meets efficiency in the production of PET bottles. Designed to address the evolving demands for high-speed and high-volume production, our blow moulding machine is ideal for producing a wide range of PET containers, from small to large sizes, for still water and mineral water applications.

Key Features and Benefits:

-

Advanced Technology Integration:

- High-Speed Performance: Our blow moulding machine incorporates the latest advancements in linear blowing technology, enabling rapid production speeds and efficient high-volume output.

-

Versatile Container Production:

- Small to Large Bottles: This machine is specially developed for the production of PET bottles in various sizes, making it suitable for both small and large container manufacturing.

-

Compact and Efficient Design:

- Space-Saving: With a strong structure and a compact footprint, the machine is designed to fit into diverse production environments while minimizing space usage.

- Low Power and Air Consumption: The machine features low power consumption and an air recovery system, reducing operational costs and improving energy efficiency.

-

Compliance with Hygiene Standards:

- Food Safety: Our linear blow moulder adheres to international food hygiene standards, ensuring that all produced containers meet stringent quality and safety requirements.

-

Touch-Screen Operation:

- User-Friendly Interface: The machine is equipped with a high-speed PLC and a touch-screen interface. Operators can easily monitor production speed, shift counts, fault diagnostics, and more directly on the HMI screen.

-

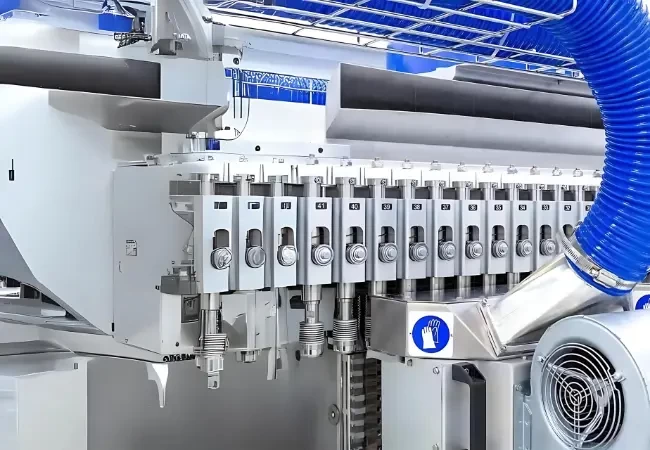

Advanced Heating and Blowing System:

- Infrared Heaters: Four stages of infrared heaters with an analog controller provide precise heating of preforms, ensuring optimal bottle shape formation with low-pressure blowing.

- Consistent Quality: The machine’s linear blowing system is designed to maintain stability and high-quality production with minimal preform weight variations.

-

Recipe Management:

- Efficient Changeovers: Blowing parameters can be saved as recipes for easy recall and efficient changeovers. This feature simplifies the setup process and reduces downtime between different production runs.

-

Automatic Preform Handling:

- Preform Unscrambler and Hopper: The machine comes equipped with an automatic preform unscrambler and hopper, streamlining the preform feeding process and enhancing overall production efficiency.