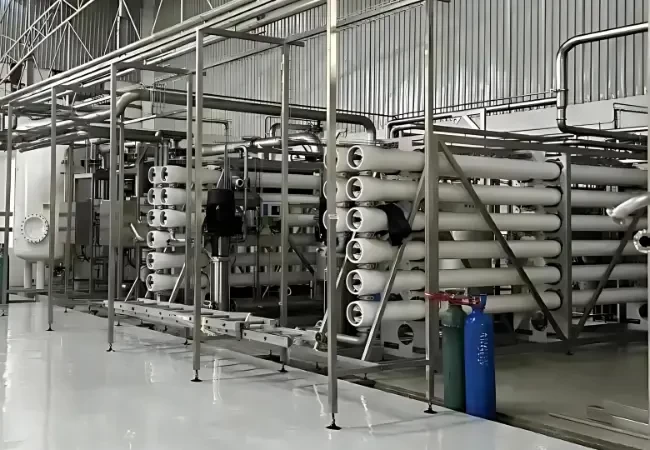

Industrial Brackish Water Reverse Osmosis System

Brackish water Reverse osmosis systems produce high purity water, removing up to 98% of dissolved inorganics and over 99% of large dissolved organics, colloids and particles. The Advanced is equipped with plastic covers granting protection and robust design. It is a plug & play unit suitable for transportation in a container and conforms to European standards.

Brackish water Reverse Osmosis Features & Benefits

- Low energy membranes result in lower operating pressure giving cost savings

- Feed salinity up to 5000 mg/l TDS (NaCl)

- 1μm pre-filtration included within the unit for membrane protection.

- Dry run monitor & pump protection

- Concentrate throttling valve for flow adjustment and concentrate recirculation.

- Instrument allocated in frontal control block part for comfortable accessibility and workability.

- Skid-mounted, standardised systems; short lead times, quick installation and start-up.

- CIP connections forwards installed.

- HMI Touchscreen "7-14" modern interface user friendly. Fully configurable and simple operation, monitoring of pressure, flow rate, conductivity and temperature values.

- Data logging

Applications

- Boiler feed

- Industrial utility water

- Water and juice production

- Biotechnologies

- Industrial process water

- Pharmaceuticals

- Reuse / recycling

- Hospitals

- Healthcare

- Laboratory

Water Treatment Systems

- Reverse Osmosis plant

- Multi Media Filter

- High Rate Solid Contact Clarifier - HRSCC

- PRO ATHENA

- BEV Systems

- PRO MINI

- HERO Modular Systems

- SeaTECH Series

- SKYLINE Seawater RO

- SeaPRO E-Series

- Turbidity Treatment

- Mineral Dosing

- Iron Removal

- Silica Removal

- Seawater Desalination

- Mixed Bed Deionizer

- Electrodeionization (EDI)

- Ozonation & UV

- Closed Circuit Reverse Osmosis

- Sewage Treatment Plant (STP)

- Effluent treatment Plant (ETP)

- Odour Control System

- Anaerobic Reactor (UASBR)

- DAF - Dissolved Air Flotation

- MBBR-Effluent treatment

- Membrane Bio Reactor

- Continuous Fill Batch Reactor

- Sequential Batch Reactor (SBR)

- Zero Liquid Discharge System