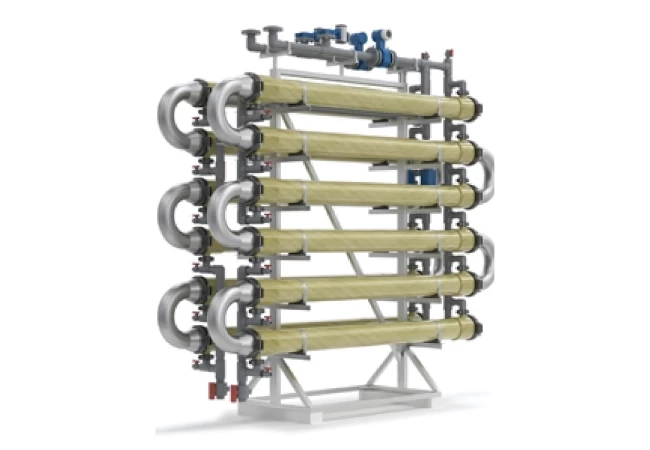

Membrane Bio Reactor (MBR)

Membrane Bioreactor (MBR) is an activated sludge treatment system with submerged membranes that improves treatment performance and consistency compared to conventional activated sludge systems by using a physical membrane barrier for liquid-solids separation instead of traditional gravity clarification. This technology complements our anaerobic technologies by aerobically polishing anaerobically pre-treated wastewater, and can also be used as a stand-alone process.

The MBR can treat wastewater from a wide variety of industries. The MBR system’s long solids retention time and physical membranes work together to provide more consistent removal of organics, ammonia, and nitrogen than conventional activated sludge systems. The biochemical oxygen demand (BOD) and total suspended solids (TSS) concentrations discharged from the process are negligible, and very low effluent phosphorus concentrations can also be reached.

Key Features of Membrane Bio Reactor

- High-Quality Effluent: MBR systems produce exceptionally clean effluent with very low concentrations of biochemical oxygen demand (BOD), total suspended solids (TSS), and phosphorus. They are capable of meeting stringent discharge limits for BOD, TSS, nitrogen, and phosphorus.

- Versatile Application: MBR technology can treat wastewater from various industries and is suitable for both standalone applications and as a polishing step following anaerobic treatment.

- Compact Footprint: The system’s design allows for a smaller footprint compared to traditional systems, making it suitable for facilities with space constraints.

- High Solids Concentration: Operates effectively at high mixed liquor suspended solids (MLSS) concentrations, ranging from 8,000 to 15,000 mg/l.

- Long Solids Retention Time: Provides extended solids retention time, which enhances the stability and efficiency of the treatment process.

- Robust Performance: Offers increased stability against fluctuations in influent characteristics, ensuring reliable operation.

- Complete Solids Retention: The membrane barrier ensures full retention of solids, contributing to process stability and high-quality effluent.

MBR systems are ideal for water reuse and direct discharge applications, delivering superior treatment performance and operational efficiency.

Request Information

Water Treatment Systems

- Reverse Osmosis plant

- Multi Media Filter

- High Rate Solid Contact Clarifier - HRSCC

- PRO ATHENA

- BEV Systems

- PRO MINI

- HERO Modular Systems

- SeaTECH Series

- SKYLINE Seawater RO

- SeaPRO E-Series

- Turbidity Treatment

- Mineral Dosing

- Iron Removal

- Silica Removal

- Seawater Desalination

- Brackish Water Reverse Osmosis (RO)

- Mixed Bed Deionizer

- Electrodeionization (EDI)

- Ozonation & UV

- Closed Circuit Reverse Osmosis

- Sewage Treatment Plant (STP)

- Effluent treatment Plant (ETP)

- Odour Control System

- Anaerobic Reactor (UASBR)

- DAF - Dissolved Air Flotation

- MBBR-Effluent treatment

- Continuous Fill Batch Reactor

- Sequential Batch Reactor (SBR)

- Zero Liquid Discharge System