Optimizing Water Management: How Grundfos Pumps Enhance Cooling Tower Efficiency

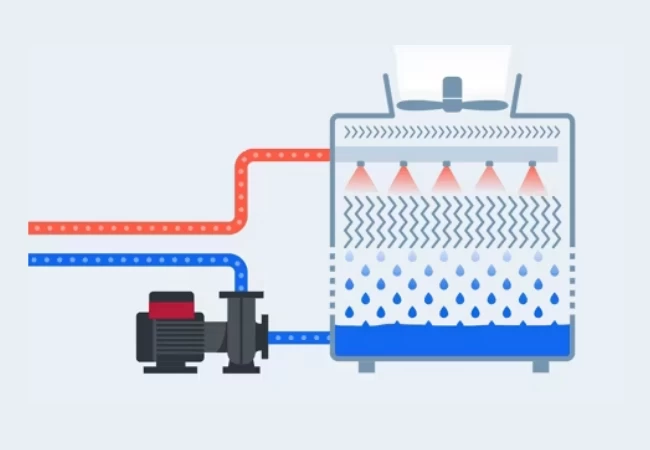

Cooling towers are crucial components of many industrial and commercial facilities, yet they often operate in the background, only drawing attention when problems arise. Properly functioning cooling towers not only enhance production processes but also contribute to significant water and energy savings. Grundfos pumps are at the forefront of solutions that address the challenges faced by cooling tower systems, providing innovative technologies that optimize performance and ensure safety.

The Importance of Effective Cooling Tower Management

In rapidly evolving industries, the efficiency of cooling towers can directly impact operational costs and environmental footprints. Common issues such as water quality control, chemical dosing, and system monitoring can lead to significant inefficiencies if not managed properly. For instance, improper chemical dosing can result in bacterial growth, risking fouling and health hazards, while unstable water levels can lead to excessive water consumption.

Advanced Solutions with Grundfos Pumps

-

Intelligent Chemical Management

Grundfos offers cutting-edge solutions that combine advanced pump technology with intelligent digital systems. Their chemical management systems provide precise dosing and monitoring capabilities, allowing for accurate control of water treatment processes. This not only helps maintain optimal water quality but also minimizes the risks associated with manual interventions.

-

Real-Time Monitoring and Automation

One of the standout features of Grundfos solutions is their ability to integrate real-time monitoring into cooling tower operations. With cloud-based systems, facility managers can access critical data anytime, improving decision-making processes. Automated alerts for chemical refills, maintenance needs, and system irregularities ensure that potential issues are addressed before they escalate, enhancing overall uptime.

-

Enhanced Safety and Compliance

Safety is paramount in any industrial setting. Grundfos pumps are designed with features that enhance user safety by ensuring that the correct chemicals are used for treatment. Additionally, the automated logging of operational data simplifies compliance reporting, reducing the burden on staff while improving accuracy.

-

Sustainable Water and Energy Management

By optimizing water management in cooling towers, Grundfos pumps contribute significantly to sustainability efforts. With intelligent systems that adjust chemical dosing based on real-time water quality measurements, facilities can achieve better water balance while reducing their overall water footprint. This aligns with the growing commitment of industries to promote environmentally responsible practices.

-

Streamlining Stakeholder Collaboration

A key advantage of Grundfos technology is its ability to facilitate communication among all stakeholders involved in cooling tower management. With transparent data sharing, everyone—from facility managers to chemical suppliers—can stay informed about system performance. This collaboration helps potential issues, leading to smoother operations and better resource management.

Related Blog Posts:

Transforming Energy Efficiency in Boiler Feed Applications with Grundfos CRNEConclusion

As industries face increasing pressures to operate efficiently while adhering to safety and sustainability standards, the role of advanced pump technology in cooling tower systems cannot be understated. Grundfos pumps offer innovative solutions that not only enhance operational efficiency but also support a commitment to reducing environmental impact. By investing in these intelligent systems, facilities can ensure their cooling towers operate at peak performance, ultimately benefiting both their bottom line and the planet.

As a trusted Grundfos pump supplier, Alantech provides top-notch and high-performing pumping solutions. The dedicated team at Alantech possesses extensive expertise in Grundfos' products. Prioritizing quality and customer satisfaction, Alantech delivers pumping solutions that meet customer’s specific requirements.