Grundfos: Ensuring Reliability and Efficiency in Parmalat's Water Treatment System

When it comes to industrial operations, particularly in the food and beverage sector, the importance of water treatment cannot be overstated. For Parmalat, a global leader in UHT long-life milk production with over 40,000 employees and operations across 27 countries, maintaining high-quality production standards is essential. At their dairy plant in Hungary, Grundfos plays a vital role in ensuring the reliability and efficiency of the plant’s water treatment system.

The Challenge: Water Treatment System for a Leading Dairy Producer

The Parmalat dairy plant in Hungary operates in a highly competitive and quality-driven industry. To maintain the highest standards of production, the plant requires a reliable and efficient water treatment system. The challenge was to design a system that would not only meet the plant’s water quality needs but also operate with minimal downtime and maximum efficiency.

Parmalat, in collaboration with CWG Hungary Ltd., the main contractor, set out to implement a water treatment system that would optimize the use of water while maintaining consistency in their operations. One of the key aspects of this system was ensuring the continuous and reliable dosing of various chemicals, such as corrosion control, biological control, oxygen scavengers, and pH regulators.

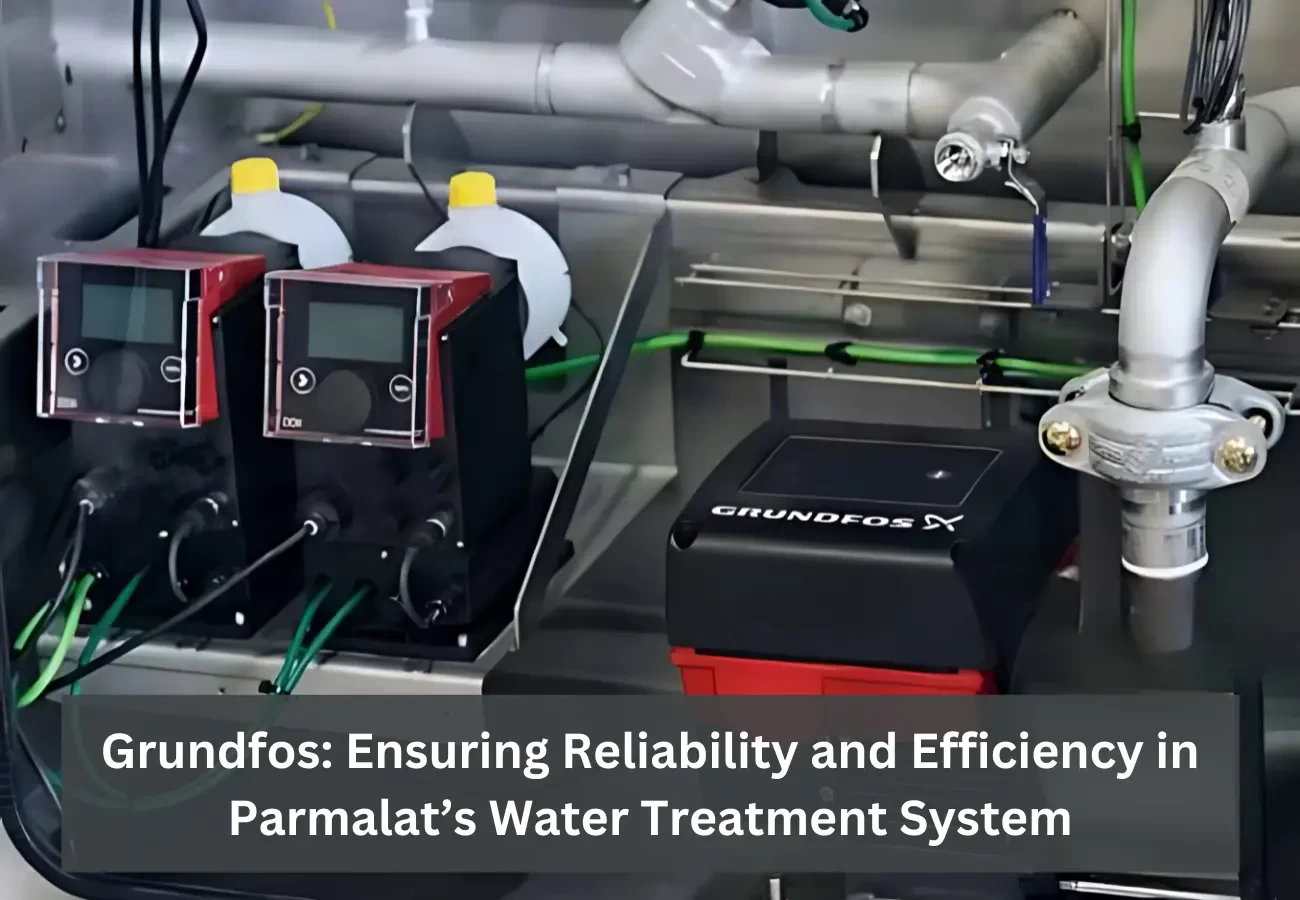

The Solution: Grundfos Digital Dosing Pumps

To meet these needs, Grundfos provided their Digital Dosing pumps, which have become an essential part of the plant's water treatment process. Grundfos’ pumps are known for their accuracy, reliability, and ease of integration, making them the ideal choice for Parmalat’s operations.

The Digital Dosing pumps at the plant are used in various critical areas, including the water-cooling system and the boiler feed system. For example:

- In the water-cooling system, a pulse-controlled DMS 8 pump administers a corrosion control chemical in precise amounts (ml/pulse).

- A DMS 2 pump automatically administers a fixed dosage of biological control chemicals based on time control from the control cabinet.

- In the boiler feed system, two DMS 8 pumps provide precise dosages of oxygen scavenger and pH regulators (ml/h).

In addition to the dosing pumps, Grundfos supplied a Hydro 2000 pressure booster and a CR 8 multistage pump to provide the necessary pressure for the water-cooling system and the reverse osmosis process, respectively.

Key Advantages: Reliability, Ease of Use, and Single-Source Supply

The Grundfos solution provided Parmalat with a comprehensive, reliable, and user-friendly water treatment system. Several key advantages were realized through the collaboration:

- Reliability and Efficiency: The Digital Dosing pumps ensure that the plant's water treatment system operates at maximum efficiency, providing accurate and consistent chemical dosages. This helps maintain optimal water quality for the production of UHT milk, while also reducing the risk of system failures.

- User-Friendly System: The easy installation and digital set-up of the pumps made the integration of the system simple and straightforward. The staff at CWG Hungary Ltd. and Parmalat found the pumps easy to build into the system and get them up and running with minimal effort.

- Rapid Service Support: Although the system is designed to operate without reserve dosing pumps, the backup comes from Grundfos’ extensive service network. The nearby service team ensures that any issues are addressed swiftly, with an agreed 24-hour limit for getting the system back up and running in case of any unforeseen disruptions.

- Single Supplier Convenience: By using Grundfos as the sole supplier for all the water treatment pumps, Parmalat benefits from a unified system where all components work seamlessly together. This simplifies maintenance and troubleshooting, as well as providing a single point of contact for any service needs.

The Outcome: A Reliable and Efficient Water Treatment System

The installation of Grundfos Digital Dosing pumps at the Parmalat dairy plant in Hungary has resulted in a reliable, efficient, and easy-to-manage water treatment system. The combination of precision dosing, user-friendly installation, and rapid service ensures that the plant can maintain high operational standards, supporting the company’s reputation as a leader in the dairy industry.

With Grundfos providing a dependable solution, Parmalat can focus on its core mission of producing the highest quality UHT long-life milk while leaving the reliability of its water treatment system in capable hands.

Conclusion

For industries where water quality and system reliability are paramount, Grundfos offers the ideal solution. By providing accurate, easy-to-integrate, and energy-efficient pumps, Grundfos ensures that operations like Parmalat’s dairy plant in Hungary can run smoothly and efficiently. The partnership between Parmalat and Grundfos highlights the value of dependable water treatment solutions, delivering performance, reliability, and peace of mind for years to come.