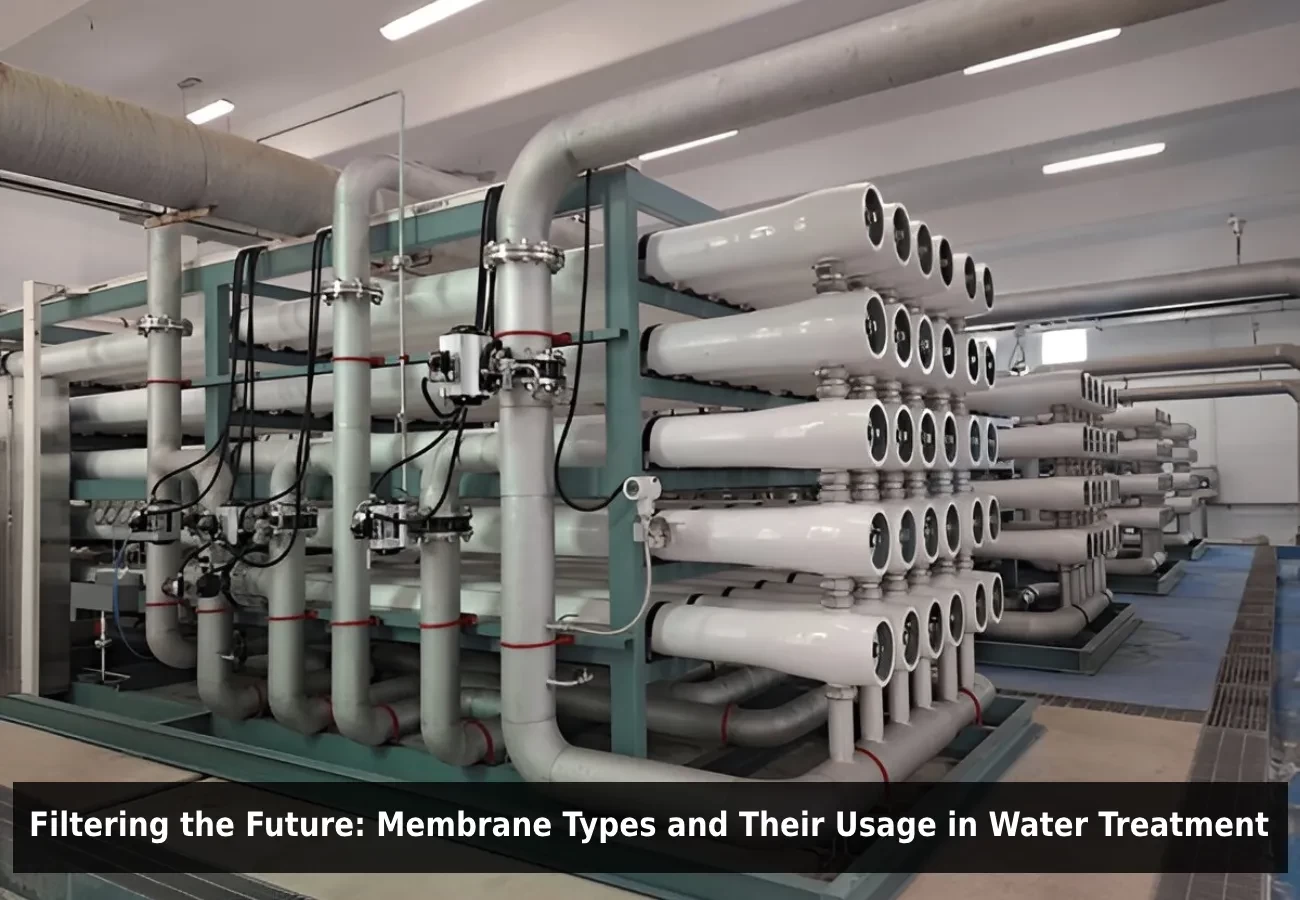

Filtering the Future: Membrane Types and Their Usage in Water Treatment

Safe and clean water is vital to life, but accessing it is growing more difficult. Technologies used to treat water from different sources depend on water treatment technologies, and membranes are becoming a dominant technology in water purification. Membrane filtration is a technology that brings several benefits such as high efficiency in removing impurities, low footprint, and relatively less energy consumption than in some other technologies. This blog explores the broad range of membrane types and their applications in water treatment.

- Microfiltration (MF):

Membranes for microfiltration are between 0.1 and 10 µm pore size. Microfiltration membranes are mainly applied to the removal of suspended particulate matter, bacteria, protozoa, and large microorganisms.

- Applications:

- Pre-treatment of reverse osmosis as well as other membrane processes.

- Potable water purification specifically for the elimination of pathogens.

- Wastewater treatment to eliminate solids.

- Filtration of liquid drinks and medicines.

- Ultrafiltration (UF):

Ultrafiltration membranes have pores that are smaller than microfiltration, typically ranging from 0.01 to 0.1 µm. They are effective in the removal of viruses, colloids, proteins, and other macromolecules.

- Application:

- Cleaning drinking water by eliminating microorganisms and large organic molecules.

- As a pre-treatment for reverse osmosis to minimize fouling.

- Treating industrial wastewater by eliminating oils and emulsions.

- Concentrating proteins and other valuable constituents in dairy and food processing.

- Nanofiltration (NF):

Nanofiltration membranes possess even finer pores, around 0.001 to 0.01 µm. They can efficiently reject divalent ions (e.g., calcium and magnesium), heavy metals, and specific organic compounds.

- Applications:

- Softening water in order to soften it.

- Heavy metal removal from industrial wastewater.

- Removal of salinity from brackish water.

- Removal of certain pollutants, such as nitrates or arsenic.

- Reverse Osmosis (RO):

Reverse osmosis membranes have the smallest pores of the most widely used membrane types, typically less than 0.001 µm. They can remove nearly all dissolved salts, minerals, and organic matter, such as bacteria and viruses.

- Applications:

- Sea and brackish water desalination.

- Purification of drinking water, eliminating impurities.

- Treatment of industrial wastewater, recovering pure water.

- Manufacturing ultrapure water for pharmaceutical and electronics industries

Also read: What Is Reverse Osmosis and Its Application

- Membrane Materials and Construction:

Not just the pore size of a membrane determines its performance; it also relies on the material used to make it and its construction.

- Polymeric Membranes: They are the most commercially available form, made of polymers like polysulfone, polyethersulfone, polyvinylidene fluoride (PVDF), and cellulose acetate. They offer the best balance of performance, expense, and durability.

- Ceramic Membranes: They are synthesized from inorganic substances like alumina, zirconia, and titania. These are stronger than polymeric membranes, chemically inert, and resistant to heat, but may be more costly.

- Composite Membranes: Composite membranes are made of several layers of various materials, often a thin selective layer supported by a porous support layer. This enables optimization of membrane performance for a given application.

- Membrane Configurations: Membranes exist in a variety of configurations, such as

- Flat Sheet: Low cost and easy to apply, but fouls easily.

- Hollow Fiber: High surface area to volume ratio, best suited for high flow rates.

- Spiral Wound: Low volume and efficient, used most commonly in RO systems.

- Tubular: Resistant to fouling and sturdy, ideal for high solids concentration.

- Determinants of Membrane Performance:

There are certain factors that could affect membrane performance in water treatment:

- Fouling: Deposition of particles, microorganisms, or organic matter on the membrane surface, reducing efficiency and flux.

- Scaling: Precipitation of minerals on the membrane surface, also reducing performance.

- Temperature: Influences membrane permeability and can have an effect on fouling.

- pH: May influence membrane integrity and performance.

- Pressure: The force behind membrane filtration, affecting flux and rejection.

- Membrane Selection for Water Treatment:

Selecting the proper membrane for a given water treatment process is determined by the following factors:

- Target Contaminants: Type and level of contaminants to be removed.

- Water Quality Requirements: Quality of treated water to be achieved.

- Flow Rate: Treated water volume.

- Cost: Initial capital and operating costs of the membrane system.

- Energy Consumption: The energy consumed by membrane filtration.

- The Future of Membrane Technology:

Research and development efforts focus on improving membrane performance, reducing fouling, and lowering costs. Trends emerging are:

- Advanced Membrane Materials: Innovative polymers, nanomaterials, and bio-inspired materials for improved performance.

- Fouling-Resistant Membranes: Designing membranes with fouling-resistant surfaces, reducing maintenance and efficiency.

- Smart Membranes: Incorporating sensors and actuators into membranes for real-time monitoring and control.

- Membrane Bioreactors (MBRs): Merging membrane filtration and biological treatment to achieve better wastewater treatment.

Membrane technology is constantly changing, providing more effective and less expensive methods of water treatment. With the increasing problem of water scarcity globally, membranes will be instrumental in providing safe and clean water for everyone. The various types of membranes and how they are applied can be understood to make this technology more beneficial in solving water purification and reusing problems.